QMJ-300S General introduction of the machine

A. This equipment is widely used in industry of toothpaste, cosmetic, drugs and food etc., it is applicable for various plastic tube and plastic-laminated-tube. It can fill-pack all kinds of cream, latex, lotion, oil and water etc. Before you use our equipment, read this user manual carefully, so that you can make a good use of our products.

This equipment use Panasonic PLC and sensor. It can automatically fill, seal, stamp batch numbers and exit tubes(with 8 tube position) . Inner-heating and outside –heating method is adopted in the heating section, which can blow hot-wind to the tube tail-ends inner wall. The parts touched with material adopt 304 stainless steel, which can proof acid, alkali and corrosion. All the channels can be unloaded fast and agilely. The material-valve can be rotated, it can be cleanout easily, so there’s no place for the dirty. Fixing organization can fix position precisely and firmly. The position-turning part can change speed by using different-frequency. Customers can adjust the working speed themselves.

Several devices such as heatproof system( to keep steady heating temp. of the material) , mixing parts, and etc can be chosen according to the customer’s demand.

Characteristic:

※ The parts touched with material adopt 304 stainless steel

※ The link parts are easy to take-down and washing

※ Uses high quality pneumatic elements

Basic parameters of the machine

1.Power supply: ~220V±10%

2.Consume :350W×2 250W×2

3.Air source(Mpa):air pressure > 0.4Mpa

4.Filling capacity(ml): 50、100、200、250(ml) as per customer demand

5.Speed: 20-40 pcs/min

6.Measure precision: ±1%

7.Dimension(mm): 1100*800*1600(net)

After packed: 1200*900*1800mm

8.Weight of the machine (kg):280㎏

QMJ-300S General introduction of the machine

A. This equipment is widely used in industry of toothpaste, cosmetic, drugs and food etc., it is applicable for various plastic tube and plastic-laminated-tube. It can fill-pack all kinds of cream, latex, lotion, oil and water etc. Before you use our equipment, read this user manual carefully, so that you can make a good use of our products.

This equipment use Panasonic PLC and sensor. It can automatically fill, seal, stamp batch numbers and exit tubes(with 8 tube position) . Inner-heating and outside –heating method is adopted in the heating section, which can blow hot-wind to the tube tail-ends inner wall. The parts touched with material adopt 304 stainless steel, which can proof acid, alkali and corrosion. All the channels can be unloaded fast and agilely. The material-valve can be rotated, it can be cleanout easily, so there’s no place for the dirty. Fixing organization can fix position precisely and firmly. The position-turning part can change speed by using different-frequency. Customers can adjust the working speed themselves.

Several devices such as heatproof system( to keep steady heating temp. of the material) , mixing parts, and etc can be chosen according to the customer’s demand.

Characteristic:

※ The parts touched with material adopt 304 stainless steel

※ The link parts are easy to take-down and washing

※ Uses high quality pneumatic elements

Basic parameters of the machine

1.Power supply: ~220V±10%

2.Consume :350W×2 250W×2

3.Air source(Mpa):air pressure > 0.4Mpa

4.Filling capacity(ml): 50、100、200、250(ml) as per customer demand

5.Speed: 20-40 pcs/min

6.Measure precision: ±1%

7.Dimension(mm): 1100*800*1600(net)

After packed: 1200*900*1800mm

8.Weight of the machine (kg):280㎏

►Very good quality Because we are professional

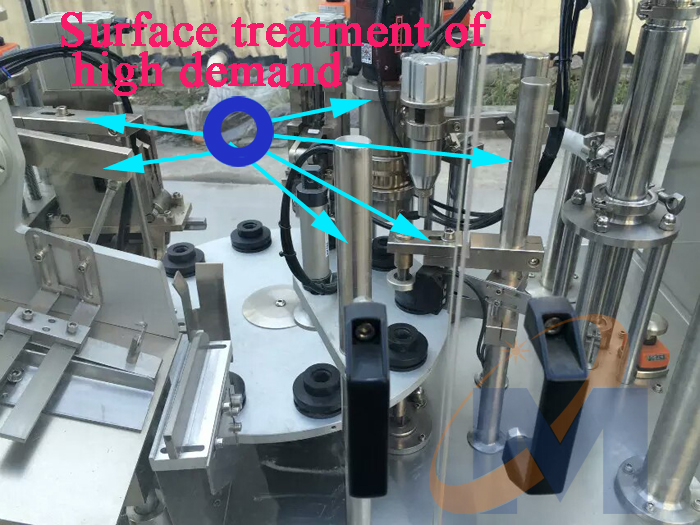

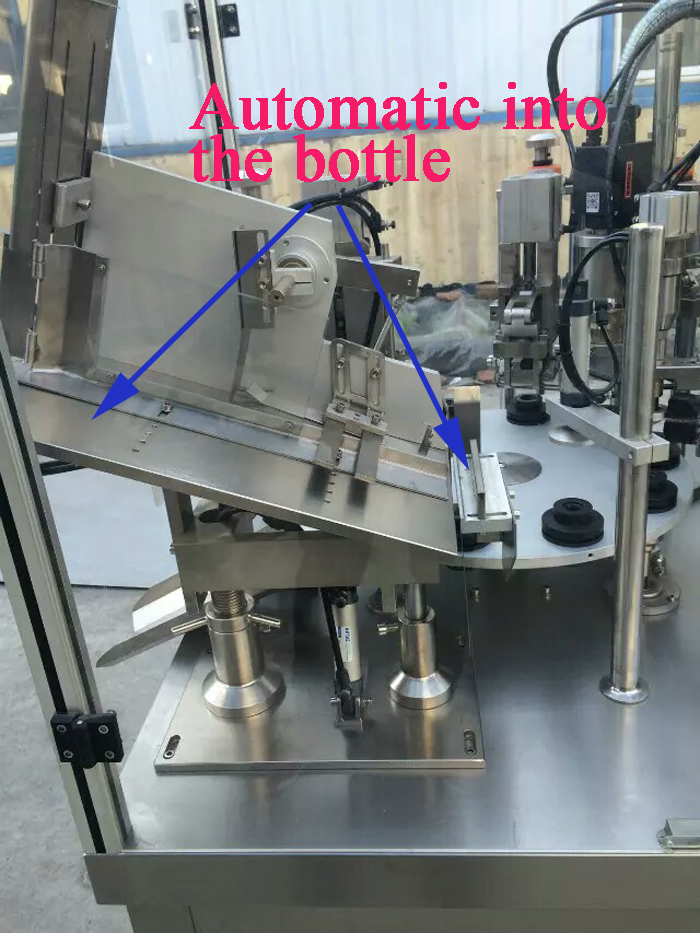

►The details of our

►The details of our

►The details of our

►The details of our

►The details of our

►The full figure

►The full figure

►The machine in the work

►The machine in the work

►Part of the product

►Part of the product

►Cleansing milk products

►Cleansing milk products

Stable, reliable, high quality

Stable, reliable, high quality